How to Reduce Costs in Electronics Manufacturing

You’re set to do everything right: Your new project will be carefully constructed to meet requirements and applications. Specifications will be carefully thought through, even for EMI/RFI regulations. You’re confident you can take care of design and engineering. But how do you control the third leg of the stool – the costs for those printed circuit boards?

To be perfectly honest, most leave the costs of printed circuit board assemblies up to chance. They send out specifications to numerous manufacturers and go with what they hope will be a low-cost provider that maintains quality. Worse, they’ll find several PCB manufacturers and piece out PCBs, and then try to hook pieces together at the end. Results never seem to go as planned. Any cost savings is usually eaten up with quality control issues or time mis-matched deliveries.

Yet you can help control the manufacturing costs of printed circuit boards and assemblies in two ways; at design and for production. We want to show you how to set yourself up for savings from the very conception of your project, and then provide what you need to know about working with a manufacturer.

Building In Cost Savings During PCB Design

- From experience you know how expensive it can be to do things twice when only once will do. For this reason, whenever possible, keep all of your PCB components on one side of the circuit board. It saves a second pass, a lot of time and extra expense.

- Use surface mount (SMT) components. Try to avoid through hole (THT) components unless you really need the extra strength THT components can provide.

- Use parts that are 0402 and 0201s or smaller. This saves valuable space and costs. Components costs are less the smaller they are and the larger components like 0805 are getting obsoleted. But on that note, here’s something to keep in mind when comparing manufacturers: Many will tell you to use 0402 or larger because it’s easier to place the larger components. They claim it will save costs. In reality this immediately should give you a glimpse into the accuracy of their process and their confidence in their quality control capabilities.

- Plan for test points. You’re going to want to test your PCB for open or short circuits and device integrity. Plan for this quality control function early in the design. Also, keep test points on one side of the board if you can. This is going to save time and money plus deliver you a better product.

- Never plan on using single-source components or products that are near the end of their life-cycle. Future availability could cause escalating prices for parts that are hard to replace later on. Figure in alternatives and you or your manufacturer should be using platforms like Silicon Expert to give you the run-down on specific components within your BOM before you finalize your product.

Savings at the Manufacturer

You’ve now designed your PCB for maximum cost savings. Here is how a good manufacturer should help optimize your savings at the next level – the build.

- Allow – in fact insist – your manufacturer will review the design before prototyping. This may seem like an unnecessary step but tools at their disposal, such as Mentor Graphics Valor DFM, will show any potential problems and prepare them for manufacturing best practices. It will save you in the long run.

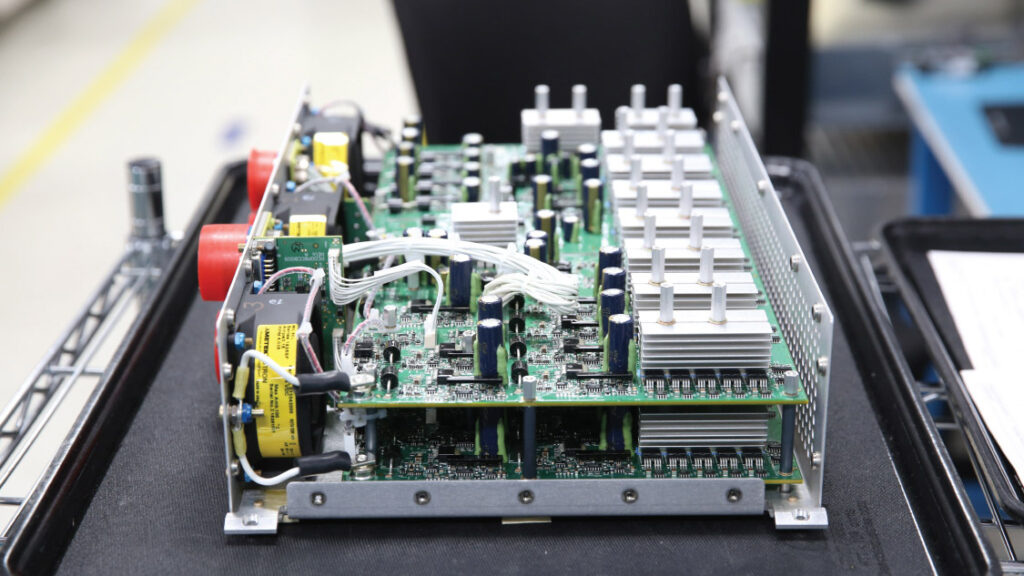

- Use a manufacturer that offers rapid prototyping. Rapid prototyping allows you to check your PCB assembly quickly for function and desired outcomes within the final application. It also allows the manufacturer to define efficient manufacturing processes before carrying out production runs. Ideally your manufacturer should offer a dedicated prototyping line so that this process is planned for without having to shut down larger run manufacturing. Rapid prototyping is a huge cost saver both now and into the future use of your product.

- Prepare to panelize. If your PCB is small or an odd shape, your manufacturer may suggest panelizing to add strength and stability to the manufacturing process. It will also save you money.

- Try to allow for longer lead times. You will not pay the same for PCBs you needed “yesterday” as you would if you had planned ahead. Stopping production of an existing order to accommodate your run is going to cost you.

- It may seem counterintuitive to use one manufacturer for all required PCBs when you have a stack of quotes on your desk that show a little savings here and a bit there, but there are uncalculated costs involved with spreading the work out. It’s almost guaranteed that something will go wrong; imperfect matching at final assembly, quality control issues that are hard to track down due to so many chefs in the kitchen blaming the others, time lags and shipping/transit costs and damage. Use one manufacturer who can handle all your needs and you’ll have fewer problems down the road while ultimately saving hidden costs – which brings us to our next cost reduction strategy:

- If your PCBA is calling for a conformal coating, choose a manufacturer who offers this as part of their manufacturing process. Overall quality control will be in the hands of one manufacturer, which provides you accountability and assurance. You’ll save delays and money because of the avoidance of shipping from one facility to another, avoid damage during transit and you won’t have to be 4th or 5th in line for conformal coatings at a place that doesn’t know you. A manufacturer that can provide and plan for conformal coatings means you’ll be next in line.

- Go with a manufacturer that can scale with your business. It’s one thing to find someone who can provide you with one hundred finished PCBs, but what if you suddenly need 10,000? If your manufacturer can’t scale you’ll be looking for someone new – adding time, costs and hassle.

Good News in the PCB Assembly Cost-Waging War

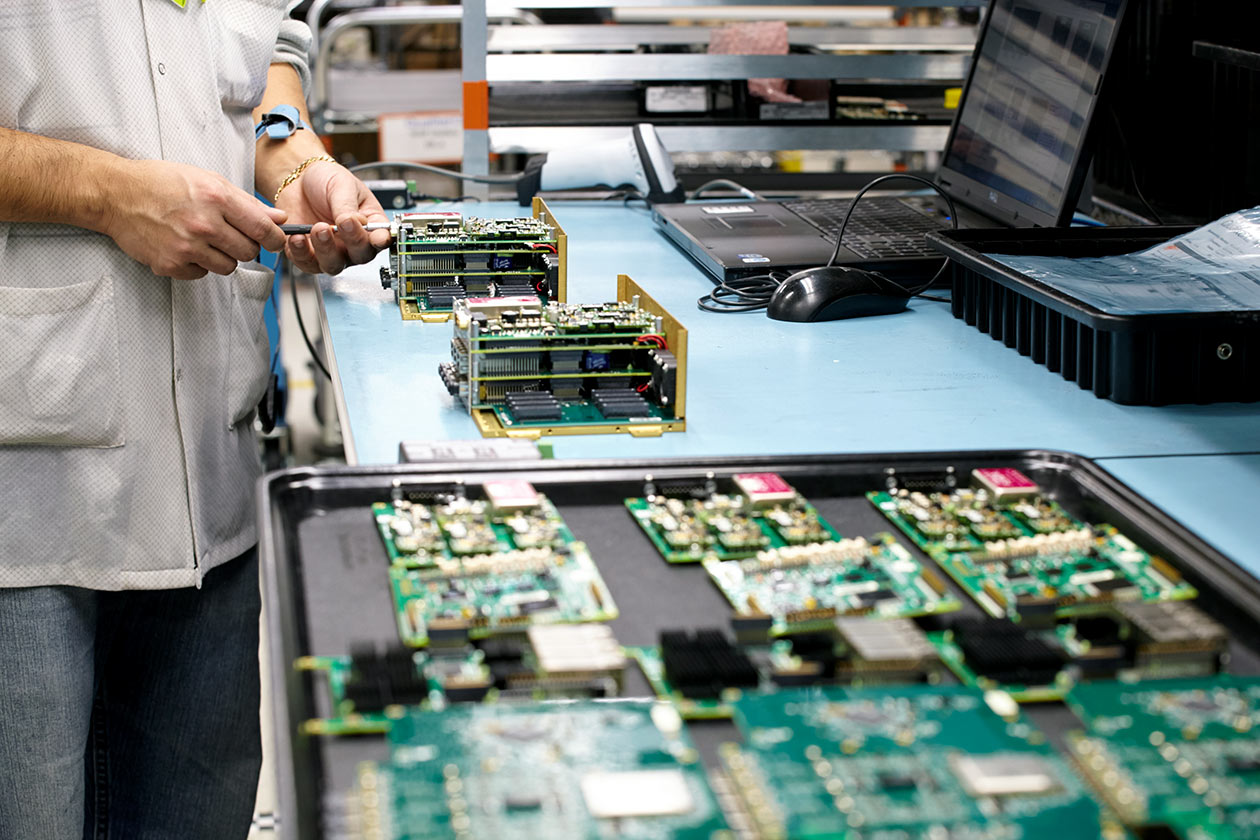

Qualitel is your ally in trying to cut costs. We have thought through your position and needs and are constantly adding to our technology and capabilities. We have a dedicated team for nothing but rapid prototypes – immediately saving you time and money. Our engineers will work with you to think about the best processes while delivering the best outcomes. The facility which houses our staff and technology for large production runs offers the best, most accurate and fastest production you’ll find while maintaining the strict quality standards we have built our reputation on. And yes, you’ll be next in line for conformal coatings, with all kinds available, when we handle your manufacturing.

But we understand the proof is in the numbers. Try our online Instant Express Quote. We think you’ll be impressed. Then let’s have a conversation about why your next printed circuit boards and assemblies should be made by Qualitel.

Contact Us

To take an in-person facility tour, meet the staff, and learn more about our unique ability to manufacture your mission-critical PCB assembly and quick-turn prototyping, contact us today!