The Risks of Offshore Manufacturing in a COVID-19 World

The coronavirus epidemic has left many manufacturers struggling to mitigate business disruptions stemming from offshore sourcing strategies. Partnering with an onshore contract manufacturer provider can lessen the impact and help you remain competitive.

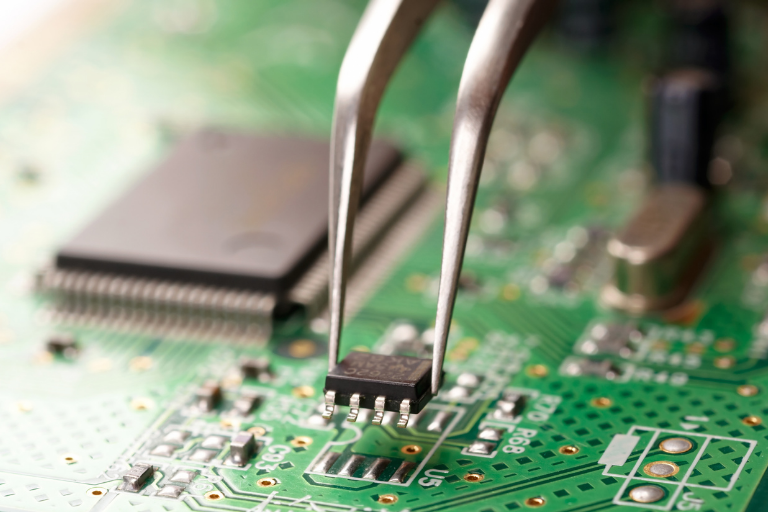

Anytime you contract with an overseas electronics manufacturing service, you face risks from delivery and production delays—now more than ever. The lower price point may be tempting, but what will you sacrifice? Here are five reasons why you should choose a domestic EMS partner in a COVID-19 environment.

Reduce Inventory

Because of unknown variables and extended lead times that come with overseas electronics manufacturing, many businesses are in the practice of purchasing excess inventory to minimize the risks. When you partner with a local manufacturer in the U.S. like Qualitel, you get faster ship times to meet your customers’ demands, which means you can order smaller quantities with increased frequency and reduce carrying costs by ordering what you need without extended forecasting.

Eliminate overseas travel

The initial outbreak of the coronavirus impacted overseas electronic contract manufacturing almost immediately, with travel restrictions from and to the U.S. Even as some restrictions have since been lifted overseas, safety concerns that the virus hasn’t been completely contained means U.S. companies are reluctant to travel. During the development phase of new PCBAs, there is no substitute for being on-site. When you partner with Qualitel, you minimize the health and safety risks associated with business travel to EMS providers that are located in quarantined areas.

Minimize Lead Times

PCBAs manufactured overseas have a long way to get back home, slowing the sales process and forecasting response—costing you valuable time and profits. The longer ship times prompt businesses to preemptively order larger inventory to avoid possible delays, which is not only costly but risky. Working with a USA-based electronics manufacturing service provider like Qualitel saves you money on logistics and valuable production time. Qualitel’s Express Prototyping facility provides quick-turn service in 1-3 weeks versus offshore service in 6-12 weeks. Our standard EMS facility provides turn around in 3-6 weeks versus offshore service in 12-18 weeks.

Optimize Communications

Perhaps one of the most important risks in offshore manufacturing of PCB Assemblies is the communications gap. Good communication is imperative to deliver a quality product. When you contract with a company where English is a second language, their level of proficiency can lead to miscommunications and project delays. Qualitel’s customer-centric philosophy is key to a profitable manufacturing partnership.

Responsiveness

It is difficult to find an industry that has not been impacted by the pandemic. As businesses reopen or adjust their strategies, Qualitel is committed to easing the transition for our partners. We will maintain constant communications to set new orders, production, and delivery dates.

Our Qualitel Express production line can get you back up to speed with its:

- Fast, turn-key quoting process within 48 hours

- State-of-the-art manufacturing facility

- Expert, dedicated staff

- Dependable quality & delivery

Contact us today for a fast, turnkey quote within 24-48 hours.